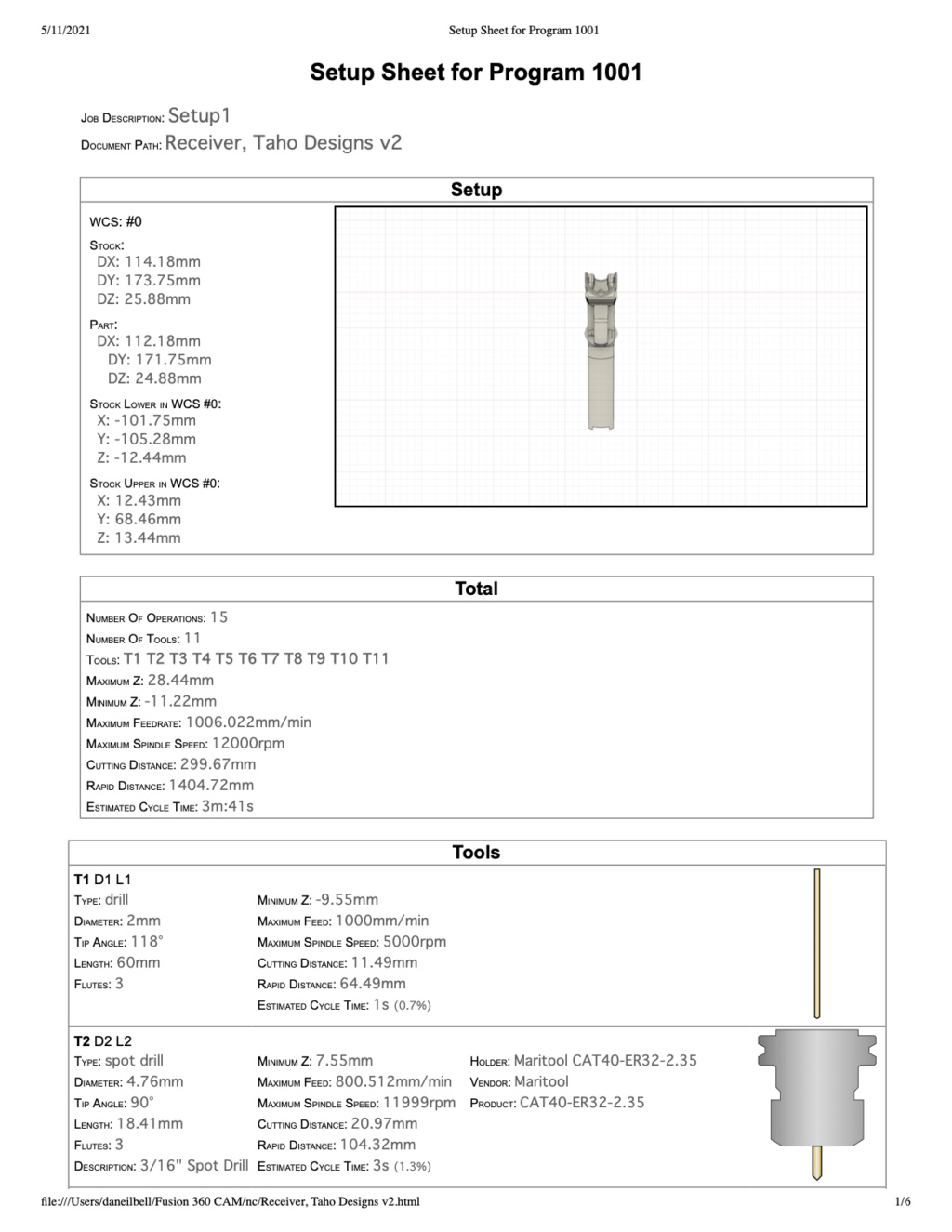

I created a post-processing file and set up instructions for my machine from a 1911 file. I set up the cam software to work with GRBL and created a simple file to drill all the holes in a 1911 receiver. I am quite new at this and would like to know if what I created looks correct and ready to run with my flex?

TEXT FROM FILES:

1001.NC:

(T2 D=4.762 CR=0 TAPER=90deg - ZMIN=7.55 - spot drill)

(T3 D=4 CR=0 TAPER=118deg - ZMIN=-10.752 - drill)

(T4 D=3 CR=0 TAPER=90deg - ZMIN=7.188 - spot drill)

(T5 D=2.794 CR=0 TAPER=118deg - ZMIN=-10.39 - drill)

(T6 D=1.587 CR=0 TAPER=118deg - ZMIN=-8.453 - drill)

(T7 D=2.5 CR=0 TAPER=118deg - ZMIN=6.247 - drill)

(T8 D=6 CR=0 TAPER=90deg - ZMIN=6.782 - spot drill)

(T9 D=5.556 CR=0 TAPER=118deg - ZMIN=-11.22 - drill)

(T10 D=3.969 CR=0 TAPER=118deg - ZMIN=-10.743 - drill)

(T11 D=3.988 CR=0 TAPER=118deg - ZMIN=-10.748 - drill)

G90 G94

G17

G21

G28 G91 Z0

G90

(Spotdrill - Spotdrill Drill 5)

T8

S12000 M3

G54

M8

G0 X-84.049 Y-76.657

Z28.442

Z18.442

Z14.55

G1 Z6.782 F1006

G0 Z18.442

X-10.947 Y-49.2

Z14.55

G1 Z6.782 F1006

G0 Z18.442

Z28.442

M5

G28 G91 Z0

G90

(Drill - Spotdrill Drill 5)

M9

T9

(CHANGE TO T9)

S5238 M3

G54

M8

G0 X-84.049 Y-76.657

Z28.442

Z18.442

Z14.55

Z11.55

G1 Z8.161 F436.6

G0 Z8.272

G1 Z6.772 F436.6

G0 Z6.883

G1 Z5.383 F436.6

G0 Z5.494

G1 Z3.994 F436.6

G0 Z4.105

G1 Z2.605 F436.6

G0 Z2.716

G1 Z1.216 F436.6

G0 Z1.327

G1 Z-0.173 F436.6

G0 Z-0.062

G1 Z-1.562 F436.6

G0 Z-1.451

G1 Z-2.951 F436.6

G0 Z-2.84

G1 Z-4.34 F436.6

G0 Z-4.229

G1 Z-5.729 F436.6

G0 Z18.442

Z-3.729

G1 Z-7.118 F436.6

G0 Z-7.007

G1 Z-8.507 F436.6

G0 Z-8.396

G1 Z-9.896 F436.6

G0 Z-9.785

G1 Z-11.22 F436.6

G0 Z18.442

X-10.947 Y-49.2

Z14.55

Z11.55

G1 Z8.161 F436.6

G0 Z8.272

G1 Z6.772 F436.6

G0 Z6.883

G1 Z5.383 F436.6

G0 Z5.494

G1 Z3.994 F436.6

G0 Z4.105

G1 Z2.605 F436.6

G0 Z2.716

G1 Z1.216 F436.6

G0 Z1.327

G1 Z-0.173 F436.6

G0 Z-0.062

G1 Z-1.562 F436.6

G0 Z-1.451

G1 Z-2.951 F436.6

G0 Z-2.84

G1 Z-4.34 F436.6

G0 Z-4.229

G1 Z-5.729 F436.6

G0 Z18.442

Z-3.729

G1 Z-7.118 F436.6

G0 Z-7.007

G1 Z-8.507 F436.6

G0 Z-8.396

G1 Z-9.896 F436.6

G0 Z-9.785

G1 Z-11.22 F436.6

G0 Z18.442

Z28.442

M5

G28 G91 Z0

G90

(Spotdrill - Spotdrill Drill 2)

M9

T4

(CHANGE TO T4)

S12000 M3

G54

M8

G0 X-6.401 Y-66.091

Z28.442

Z18.442

Z14.55

G1 Z8.153 F508

G0 Z18.442

Z28.442

(Spotdrill - Spotdrill Drill 3)

X7.379 Y-58.928

Z28.442

Z18.442

Z12.976

G1 Z7.188 F508

G0 Z18.442

Z28.442

(Spotdrill - Spotdrill Drill 4)

X1.93 Y-55.971

Z28.442

Z18.442

Z14.55

G1 Z8.296 F508

G0 Z18.442

Y-35.611

Z14.55

G1 Z8.296 F508

G0 Z18.442

Z28.442

M5

G28 G91 Z0

G90

(Drill - Spotdrill Drill 4)

M9

T7

(CHANGE TO T7)

S11643 M3

G54

M8

G0 X1.93 Y-55.971

Z28.442

Z18.442

Z14.55

Z11.55

G1 Z8.925 F436.6

G0 Z9.025

G1 Z8.3 F436.6

G0 Z8.4

G1 Z7.675 F436.6

G0 Z7.775

G1 Z7.05 F436.6

G0 Z7.15

G1 Z6.425 F436.6

G0 Z6.525

G1 Z6.247 F436.6

G0 Z18.442

Y-35.611

Z14.55

Z11.55

G1 Z8.925 F436.6

G0 Z9.025

G1 Z8.3 F436.6

G0 Z8.4

G1 Z7.675 F436.6

G0 Z7.775

G1 Z7.05 F436.6

G0 Z7.15

G1 Z6.425 F436.6

G0 Z6.525

G1 Z6.247 F436.6

G0 Z18.442

Z28.442

M5

G28 G91 Z0

G90

(Drill - Spotdrill Drill 3)

M9

T6

(CHANGE TO T6)

S11999 M3

G54

M8

G0 X7.379 Y-58.928

Z28.442

Z18.442

Z12.976

Z9.976

G1 Z7.579 F285.7

G0 Z7.679

G1 Z7.182 F285.7

G0 Z7.282

G1 Z6.785 F285.7

G0 Z6.885

G1 Z6.388 F285.7

G0 Z6.488

G1 Z5.991 F285.7

G0 Z6.091

G1 Z5.594 F285.7

G0 Z5.694

G1 Z5.197 F285.7

G0 Z5.297

G1 Z4.801 F285.7

G0 Z4.901

G1 Z4.404 F285.7

G0 Z4.504

G1 Z4.007 F285.7

G0 Z4.107

G1 Z3.61 F285.7

G0 Z3.71

G1 Z3.213 F285.7

G0 Z18.442

Z5.213

G1 Z2.816 F285.7

G0 Z2.916

G1 Z2.419 F285.7

G0 Z2.519

G1 Z2.022 F285.7

G0 Z2.122

G1 Z1.626 F285.7

G0 Z1.726

G1 Z1.229 F285.7

G0 Z1.329

G1 Z0.832 F285.7

G0 Z0.932

G1 Z0.435 F285.7

G0 Z0.535

G1 Z0.038 F285.7

G0 Z0.138

G1 Z-0.359 F285.7

G0 Z-0.259

G1 Z-0.756 F285.7

G0 Z-0.656

G1 Z-1.153 F285.7

G0 Z-1.053

G1 Z-1.549 F285.7

G0 Z18.442

Z0.451

G1 Z-1.946 F285.7

G0 Z-1.846

G1 Z-2.343 F285.7

G0 Z-2.243

G1 Z-2.74 F285.7

G0 Z-2.64

G1 Z-3.137 F285.7

G0 Z-3.037

G1 Z-3.534 F285.7

G0 Z-3.434

G1 Z-3.931 F285.7

G0 Z-3.831

G1 Z-4.328 F285.7

G0 Z-4.228

G1 Z-4.724 F285.7

G0 Z-4.624

G1 Z-5.121 F285.7

G0 Z-5.021

G1 Z-5.518 F285.7

G0 Z-5.418

G1 Z-5.915 F285.7

G0 Z-5.815

G1 Z-6.312 F285.7

G0 Z18.442

Z-4.312

G1 Z-6.709 F285.7

G0 Z-6.609

G1 Z-7.106 F285.7

G0 Z-7.006

G1 Z-7.503 F285.7

G0 Z-7.403

G1 Z-7.899 F285.7

G0 Z-7.799

G1 Z-8.296 F285.7

G0 Z-8.196

G1 Z-8.453 F285.7

G0 Z18.442

Z28.442

M5

G28 G91 Z0

G90

(Drill - Spotdrill Drill 2)

M9

T5

(CHANGE TO T5)

S10417 M3

G54

M8

G0 X-6.401 Y-66.091

Z28.442

Z18.442

Z14.55

Z11.55

G1 Z8.852 F436.6

G0 Z8.952

G1 Z8.153 F436.6

G0 Z8.253

G1 Z7.455 F436.6

G0 Z7.555

G1 Z6.756 F436.6

G0 Z6.856

G1 Z6.058 F436.6

G0 Z6.158

G1 Z5.359 F436.6

G0 Z5.459

G1 Z4.661 F436.6

G0 Z4.761

G1 Z3.962 F436.6

G0 Z4.062

G1 Z3.264 F436.6

G0 Z3.364

G1 Z2.565 F436.6

G0 Z2.665

G1 Z1.867 F436.6

G0 Z1.967

G1 Z1.168 F436.6

G0 Z18.442

Z3.168

G1 Z0.47 F436.6

G0 Z0.57

G1 Z-0.229 F436.6

G0 Z-0.129

G1 Z-0.927 F436.6

G0 Z-0.827

G1 Z-1.626 F436.6

G0 Z-1.526

G1 Z-2.324 F436.6

G0 Z-2.224

G1 Z-3.023 F436.6

G0 Z-2.923

G1 Z-3.721 F436.6

G0 Z-3.621

G1 Z-4.42 F436.6

G0 Z-4.32

G1 Z-5.118 F436.6

G0 Z-5.018

G1 Z-5.817 F436.6

G0 Z-5.717

G1 Z-6.515 F436.6

G0 Z-6.415

G1 Z-7.214 F436.6

G0 Z18.442

Z-5.214

G1 Z-7.912 F436.6

G0 Z-7.812

G1 Z-8.611 F436.6

G0 Z-8.511

G1 Z-9.309 F436.6

G0 Z-9.209

G1 Z-10.008 F436.6

G0 Z-9.908

G1 Z-10.39 F436.6

G0 Z18.442

Z28.442

M5

G28 G91 Z0

G90

(Spotdrill - Spotdrill Drill)

M9

T2

(CHANGE TO T2)

S11999 M3

G54

M8

G0 X0.406 Y-75.514

Z28.442

Z18.442

Z14.55

G1 Z7.55 F800.5

G0 Z18.442

Z28.442

(Spotdrill - Spotdrill Drill 6)

X-5.334 Y-85.547

Z28.442

Z18.442

Z14.55

G1 Z7.572 F800.5

G0 Z18.442

Z28.442

(Spotdrill - Spotdrill Drill 7)

X-91.313 Y-95.25

Z28.442

Z18.442

Z14.55

G1 Z7.556 F800.5

G0 Z18.442

Z28.442

M5

G28 G91 Z0

G90

(Drill - Spotdrill Drill 7)

M9

T11

(CHANGE TO T11)

S7299 M3

G54

M8

G0 X-91.313 Y-95.25

Z28.442

Z18.442

Z14.55

Z11.55

G1 Z8.553 F436.6

G0 Z8.653

G1 Z7.556 F436.6

G0 Z7.656

G1 Z6.56 F436.6

G0 Z6.66

G1 Z5.563 F436.6

G0 Z5.663

G1 Z4.566 F436.6

G0 Z4.666

G1 Z3.569 F436.6

G0 Z3.669

G1 Z2.572 F436.6

G0 Z2.672

G1 Z1.575 F436.6

G0 Z1.675

G1 Z0.578 F436.6

G0 Z0.678

G1 Z-0.419 F436.6

G0 Z-0.319

G1 Z-1.416 F436.6

G0 Z18.442

Z0.584

G1 Z-2.413 F436.6

G0 Z-2.313

G1 Z-3.41 F436.6

G0 Z-3.31

G1 Z-4.407 F436.6

G0 Z-4.307

G1 Z-5.404 F436.6

G0 Z-5.304

G1 Z-6.401 F436.6

G0 Z-6.301

G1 Z-7.398 F436.6

G0 Z-7.298

G1 Z-8.395 F436.6

G0 Z-8.295

G1 Z-9.392 F436.6

G0 Z-9.292

G1 Z-10.389 F436.6

G0 Z-10.289

G1 Z-10.748 F436.6

G0 Z18.442

Z28.442

M5

G28 G91 Z0

G90

(Drill - Spotdrill Drill 6)

M9

T10

(CHANGE TO T10)

S7334 M3

G54

M8

G0 X-5.334 Y-85.547

Z28.442

Z18.442

Z14.55

Z11.55

G1 Z8.558 F436.6

G0 Z8.658

G1 Z7.566 F436.6

G0 Z7.666

G1 Z6.574 F436.6

G0 Z6.674

G1 Z5.582 F436.6

G0 Z5.682

G1 Z4.589 F436.6

G0 Z4.689

G1 Z3.597 F436.6

G0 Z3.697

G1 Z2.605 F436.6

G0 Z2.705

G1 Z1.613 F436.6

G0 Z1.713

G1 Z0.621 F436.6

G0 Z0.721

G1 Z-0.371 F436.6

G0 Z-0.271

G1 Z-1.364 F436.6

G0 Z18.442

Z0.636

G1 Z-2.356 F436.6

G0 Z-2.256

G1 Z-3.348 F436.6

G0 Z-3.248

G1 Z-4.34 F436.6

G0 Z-4.24

G1 Z-5.332 F436.6

G0 Z-5.232

G1 Z-6.325 F436.6

G0 Z-6.225

G1 Z-7.317 F436.6

G0 Z-7.217

G1 Z-8.309 F436.6

G0 Z-8.209

G1 Z-9.301 F436.6

G0 Z-9.201

G1 Z-10.293 F436.6

G0 Z-10.193

G1 Z-10.743 F436.6

G0 Z18.442

Z28.442

M5

G28 G91 Z0

G90

(Drill - Spotdrill Drill)

M9

T3

(CHANGE TO T3)

S7277 M3

G54

M8

G0 X0.406 Y-75.514

Z28.442

Z18.442

Z14.55

Z11.55

G1 Z8.55 F436.6

G0 Z8.65

G1 Z7.55 F436.6

G0 Z7.65

G1 Z6.55 F436.6

G0 Z6.65

G1 Z5.55 F436.6

G0 Z5.65

G1 Z4.55 F436.6

G0 Z4.65

G1 Z3.55 F436.6

G0 Z3.65

G1 Z2.55 F436.6

G0 Z2.65

G1 Z1.55 F436.6

G0 Z1.65

G1 Z0.55 F436.6

G0 Z0.65

G1 Z-0.45 F436.6

G0 Z-0.35

G1 Z-1.45 F436.6

G0 Z18.442

Z0.55

G1 Z-2.45 F436.6

G0 Z-2.35

G1 Z-3.45 F436.6

G0 Z-3.35

G1 Z-4.45 F436.6

G0 Z-4.35

G1 Z-5.45 F436.6

G0 Z-5.35

G1 Z-6.45 F436.6

G0 Z-6.35

G1 Z-7.45 F436.6

G0 Z-7.35

G1 Z-8.45 F436.6

G0 Z-8.35

G1 Z-9.45 F436.6

G0 Z-9.35

G1 Z-10.45 F436.6

G0 Z-10.35

G1 Z-10.752 F436.6

G0 Z18.442

Z28.442

M9

G28 G91 Z0

G90

G28 G91 X0 Y0

G90

M5

M30

Images from setup file: